Roller Furling Designs and Applications

Since the first conceptual idea of sailboat roller furling was developed in 1907 by Major E du Boulay in England, the "build a better mousetrap" philosophy has improved the design and performance of many roller furling systems which is a positive for sailors.

There have been many years of debate and interpretation by sailors, rigging experts and “armchair” critics about systems and applications.

The result can often be a very confusing and sometimes uninformed opinion base by some authors of what is available and what works best.

The Alado Roller Furler

Self-Standing /External Halyard(s) / No Swivels or Bearings to Fail

Alado Roller Furler uses a simple but effective design that addresses three very important aspects that appeals to cruisers and racers alike.

NO Swivels or Bearings

This means zero chance of Jib Halyard Wrap and Failure.

If you have experienced other roller furling systems that use a Jib Halyard to "lift" the sail up, then you probably know that a swivel must be used to prevent twisting of the halyard. But..., what happens when the swivel ceases to work? The Jib Halyard becomes twisted and eventually breaks...leaving you without a sail.

Similarly, with bearing loaded drum systems, if the bearings fail, you are either unable to deploy or even worse, unable to retract.

External /Independent Halyard(s)

Install one or two halyards and use either as a system spare or use both to be used with the included double luff feeds.

The independent halyards run along the outside of Alado's exclusive interlocking aluminum foils.

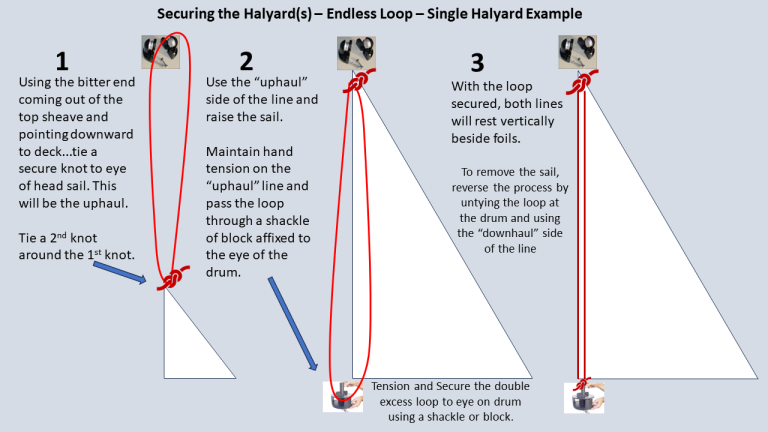

Form an "endless loop" of each halyard between the Top Sheave and the Drum with the bitter ends both fastened to the top of the sail and the excess line is fastened to the Drum.

(1) This allows the sail(s) to be hoisted independently.

(2) Full tension can be applied without affecting the shape of the sail under any wind load and does not put any tension on the forestay rigging.

(3) "What you see is what you get" meaning that a visual inspection of the halyards is possible just like all external halyards

(4) this frees up the Jib Halyard for other uses such as winching a dinghy on deck, rescuing an overboard object and even making fast that favorite Bow Hammock!

No Mast Climbing - Installs on deck.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.