The Alado Drum Design

Innovative Engineering for Simplicity

The Alado Drum is designed to spin on its own axis, eliminating the need for ball bearings which can break and jam.

Using a Central Aluminum Bushing covered by a Delrin Sleeve offers many years of maintenance and worry-free sailing.

Water can act as a conductor of electricity depending on the minerals known as the measurement of siemens. Depending on where you sail, you may have higher than normal levels of minerals in your rain or water causing increased conductivity.

Rarely, this conductivity can result in galvanic reactions caused over time to the plastic and aluminum.

The symptoms that you may notice (especially after no use for extended periods) are that the drum is getting harder to turn.

If you are the Original Purchaser of your Alado Roller Furler you may qualify for our Lifetime Warranty.

If not, then please continue reading this article.

Servicing the Alado Drum

Before you can service of the drum you will need to fully remove the drum from the forestay.

Please follow the reverse steps of the Installation Manual, taking care not to damage or lose any parts in the process.

Best Practices before you start work

Secure the bow area with a cover or tarp to prevent any parts jumping overboard.

Pick a day when the wind is manageable. No wind is best.

Remove the Drum from Forestay

Follow the reverse steps of the Installation Guide.

Be sure to secure the mast with a spare halyard before loosening the forestay.

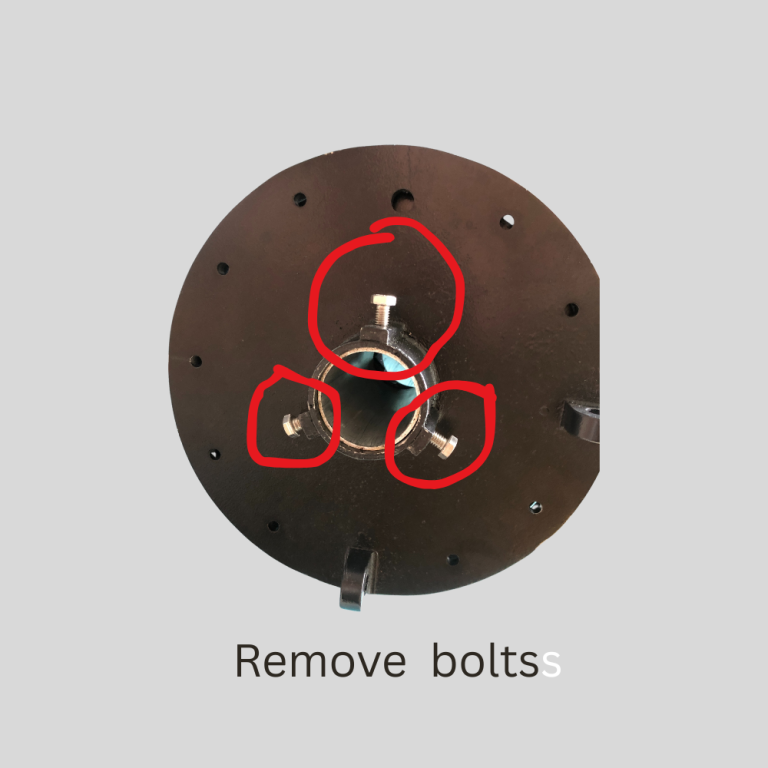

Removing the bolts from the drum

Try to use a socket with a driver that will give you sufficient leverage but allows you to feel if the bolt is seized.

If the bolt is seized spray penetrating oil and let sit for at least a day.

Remove the bolts using equal turns on each.

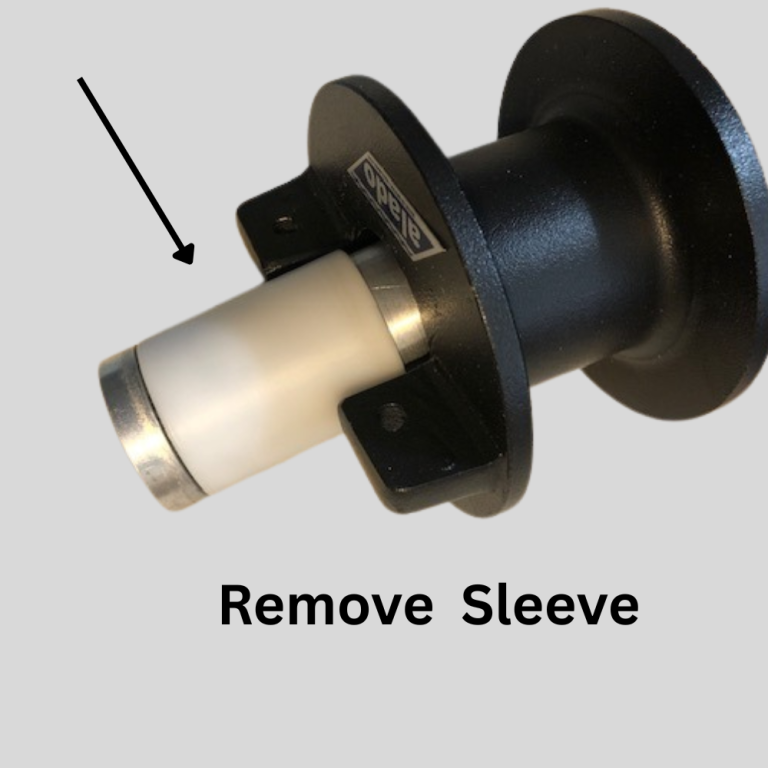

Removal of bushing, washers & sleeve.

Remove the Washers

Sand with Emery Cloth

Removal of the bushing, washers and sleeve is straight forward but be careful not to crack the plastic sleeve. It may be seized to the aluminum or if the bushing is completely seized and won't slide out, you will need to immerse in KROIL penetrating oil for at least 24 - 48 hours.

Or you can try to work with a rubber mallet and/or piece of dowel or PVC pipe.

Be careful not to hit metal on metal to any part of the drum or you will break the casting.

Soaking in Kroil is our preference to prevent any damage to bushing.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.